Ultrasonic welding

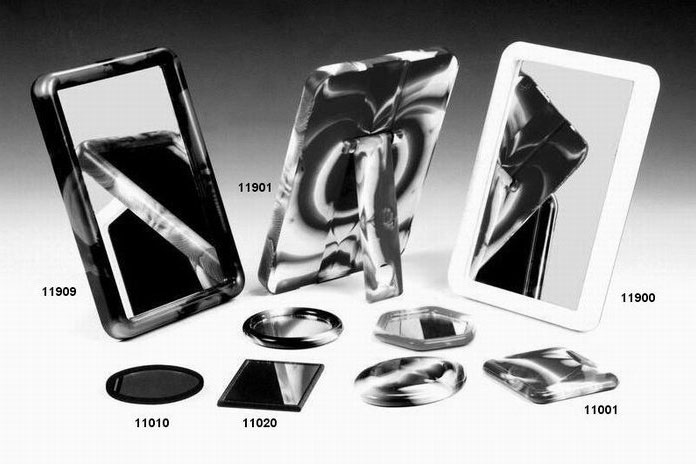

With ultrasonic plastic welding we make particulary hair curlers, hair brushes and mirrors, where the quality and solidity of the bonds is very important.

With ultrasonic plastic welding we make particulary hair curlers, hair brushes and mirrors, where the quality and solidity of the bonds is very important.

Ultrasonic plastic welding is the joining or reforming of thermoplastics through the use of heat generated from high-frequency mechanical motion. It is accomplished by converting high-frequency electrical energy into high-frequency mechanical motion. That mechanical motion, along with applied force, creates frictional heat at the plastic components’ mating surfaces (joint area) so the plastic material will melt and form a molecular bond between the parts.